Depuis sa création il y a presque 40 ans, Startech conçoit et fabrique des machines spéciales industrielles de précision, et en a fait aujourd’hui son cœur de métier.

Nous fabriquons principalement deux grandes familles de machines spéciales sur-mesure :

Nous sommes également spécialisés dans la fabrication de machines transfert, machines à haute productivité, qui sauront répondre efficacement, et dans des budgets raisonnables, à vos impératifs de production.

Si on pense immédiatement aux applications où une machine CNC « standard » (centre verticaux jusqu’à 5 axes continus ou tours) ne peut pas être utilisée parce que la pièce à réaliser est trop complexe, ce cas de figure ne représente qu’une petite partie des machines spéciales d’usinage que nous fabriquons.

Le recours à nos machines dédiées se fait par nécessité dans 20% des cas seulement.

Dans 80% des cas, nos clients optent pour nos machines spéciales par choix stratégique et non par défaut, en dépit d’un procédé « traditionnel » longtemps préféré pour sa flexibilité, car nos machines offrent un atout incomparable : leur productivité.

Une machine spéciale de précision peut diviser au minimum par 2 le temps de production d’une famille de pièce en comparaison avec une CNC « standard ».

Exemple : maillon pour bracelet horloger

Nos clients se répartissent principalement dans les trois secteurs d’activités suivants : Horlogerie, Automobile et Médical.

Cependant, nous sommes ouverts à tous tant que le projet rentre dans notre cadre de compétence, et fabriquons régulièrement des machines spéciales sur-mesure pour d’autres secteurs d’activité ayant un besoin combiné de précision et de productivité (coutellerie, serrurerie, zinguerie etc…).

Si votre projet est déjà bien avancé, vous pouvez nous consulter directement en envoyant votre cahier des charges, sinon, nous pouvons vous aider à le réaliser conjointement, de manière à répondre au mieux à vos besoins.

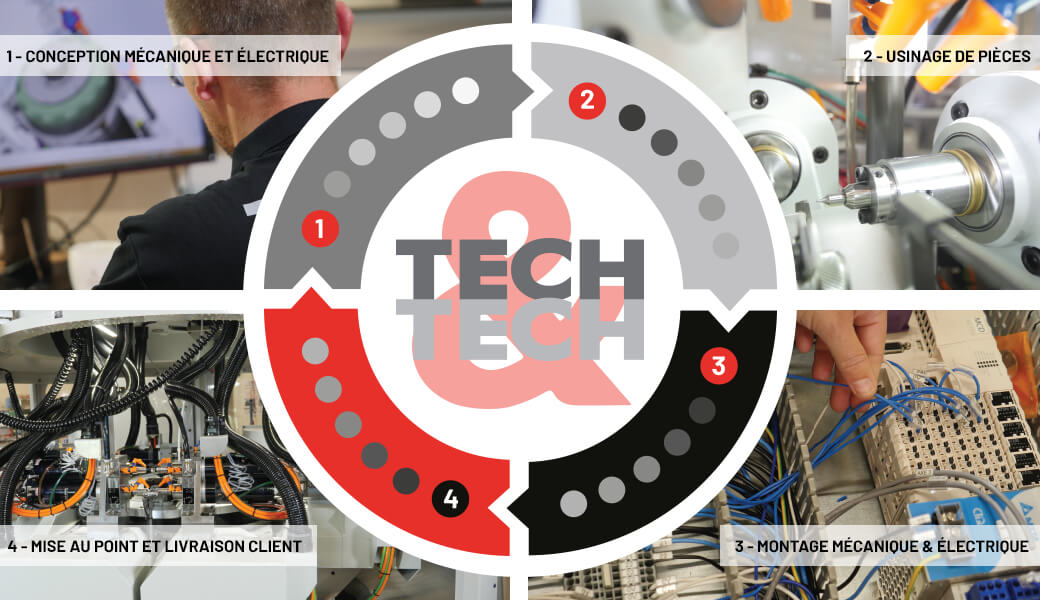

Nous sommes fiers de maîtriser le processus de conception d’une machine spéciale, et de pouvoir vous apporter notre expertise tout au long de la fabrication.

Nos bureaux d’étude mécaniques et électriques réalisent l’étude complète de la machine, puis nous fabriquons les pièces en interne grâce à un atelier d’usinage moderne. Nos équipes de monteurs, câbleurs, programmateurs et automaticiens réalisent ensuite l’assemblage et la mise au point de la machine.

les 4 postes essentiels dans la fabrication d’une machine spéciale sur-mesure sont maîtrisés par l’entreprise.

Peu importe votre secteur d’activité, n’hésitez pas à nous contacter, nous saurons vous répondre sur la faisabilité et chiffrer votre projet dans les plus brefs délais.